| Index | Unit | Grade | ||||||||

| SG1 | SG2 | SG3 | SG4 | SG5 | SG6 | SG7 | SG8 | |||

| Viscosity No. | Ml/g | 156-144 | 143-136 | 135-127 | 126-119 | 118-107 | 106-96 | 95-87 | 86-73 | |

| K Value | 76-75 | 74-73 | 72-71 | 70-69 | 68-66 | 65-63 | 62-60 | 59-55 | ||

| Average degree of polymerization | 1785-1536 | 1535-1371 | 1350-1250 | 1250-1150 | 1100-1000 | 950-850 | 750-650 | 740-650 | ||

| Foreign Particle | 30 max | 30 max | 30 max | 30 max | 30 max | 30 max | 40 max | 40 max | ||

| Volatile Matter | % | 0.4 max | 0.4 max | 0.4 max | 0.4 max | 0.4 max | 0.4 max | 0.4 max | 0.4 max | |

| Apparent Density | g/ml | 0.42 min | 0.42 min | 0.42 min | 0.45 min | 0.45 min | 0.45 min | 0.45 min | 0.45 min | |

| Particle Size | 0.25mm Sieve | % | 2.0 max | 2.0 max | 2.0 max | 2.0 max | 2.0 max | 2.0 max | 2.0 max | 2.0 max |

| 0.063 mm Sieve | 90 min | 90 min | 90 min | 90 min | 90 min | 90 min | 90 min | 90 min | ||

| No. of fish eye/400cm2 | 40 max | 40 max | 40 max | 40 max | 40 max | 50 max | 50 max | 50 max | ||

| Plasticizer absorption of 100g resin | G | 25 min | 25 min | 25 min | 22 min | 17 min | 15 min | 14 min | 14 min | |

| VCM Residue | Ppm | 10 max | 10 max | 10 max | 10 max | 10 max | 10 max | 10 max | 10 max | |

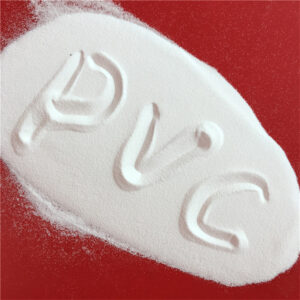

Low Viscocity Poly Vinyl Chloride (PVC) SG8

CAS Number:

9002-86-2

Other Trading Names:

- White powder PVC Resin

- PVC Hompolymer Resin

- Asaflex 805

- K-Resin KRO03

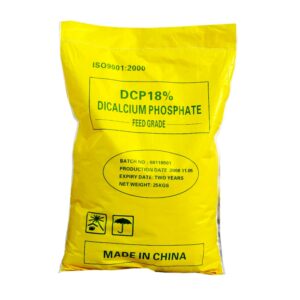

Type of Packaging :

- 25kg net paper-plastic bags

HS Code:

390410

Low Viscosity PVC Resin SG8 – Engineered for High-Speed Processing and Precision Applications

Low Viscosity Polyvinyl Chloride (PVC) Resin SG8 represents a specialized suspension-grade polymer formulated explicitly for high-flow manufacturing processes. Consequently, this resin delivers exceptionally smooth processing characteristics, making it the ideal choice for intricate injection molding, high-speed extrusion, and other applications where rapid cycle times and fine detail reproduction are critical. Therefore, manufacturers seeking to optimize production efficiency and product quality consistently select SG8 for its superior performance.

Primary Industrial Applications and Processing Benefits

We engineer PVC SG8 to meet the demands of advanced, high-output manufacturing, providing distinct advantages in key areas.

-

High-Speed Injection Molding: Primarily, this resin excels in thin-wall and complex injection molding. Its low melt viscosity allows it to fill intricate molds quickly and completely, thereby reducing cycle times and minimizing defects in precision components like electrical accessories, fittings, and consumer goods.

-

High-Speed Extrusion: Furthermore, SG8 is perfectly suited for high-speed extrusion of pipes, profiles, and sheets. The enhanced flow properties ensure stable processing at elevated output rates, significantly boosting production line efficiency.

-

Wire and Cable Coating: Additionally, the resin performs superbly in wire coating and jacketing applications. Its excellent flow ensures uniform, concentric insulation layers at high line speeds, directly contributing to consistent product quality.

-

Transparent and Specialty Compounds: Finally, due to its low inherent coloration and excellent clarity in formulations, SG8 serves as an excellent base for transparent and high-clarity rigid PVC products, meeting strict aesthetic requirements.

Key Specifications and Performance Attributes

PVC Resin SG8 guarantees enhanced processability through its specific technical profile, which is designed for speed and precision.

-

K-Value: 57 – 60 (Low Molecular Weight / Low Viscosity)

-

Appearance: White, free-flowing powder

-

Bulk Density: 0.50 – 0.58 g/ml

-

VCM Residual: ≤ 5 ppm

-

Porosity: Controlled porosity for tailored additive absorption.

-

Thermal Stability: Excellent stability to withstand high shear and temperature conditions during fast processing.

-

Core Advantage: It facilitates faster production cycles, lowers energy consumption during processing, and enables the manufacture of highly detailed and complex parts with exceptional consistency.

Wholesale Supplier and Global Export Partnership

As a dedicated global supplier, we provide a reliable and high-performance material stream for manufacturers focused on advanced production.

-

Guaranteed High-Flow Consistency: We produce SG8 to exacting standards, ensuring every batch delivers the predictable low viscosity required for your high-speed processes.

-

Optimized Bulk Packaging Solutions: The resin is available in 25 kg bags, 500/1000 kg jumbo bags (FIBCs), and bulk tanker loads, designed for seamless integration into automated feeding systems.

-

Competitive Export Pricing for Volume: We offer strategic wholesale pricing structured for high-volume injection molders, extruders, wire & cable producers, and international compounders who prioritize efficiency.

-

Efficient Global Logistics Network: Our supply chain expertise ensures timely delivery via containers or bulk vessels, fully supported by SDS, COA, and all export documentation.

-

Technical Processing Collaboration: We provide detailed technical data and flow characteristics to help you fully leverage the high-speed potential of SG8 in your specific applications.