| Index | Value |

| O – Isopropyl – N – Ethyl Thionocarbamate % ≥ | 95 % |

| Isopropyl Alcohol % ≤ | 2.0% |

| Diethyl Thiourea | 2.0% |

| Density | 990 – 1004 kg/m3 |

| Expiry Date | 1 year or 12 months |

Isopropyl Ethyl Thionocarbamate / O – Isopropyl – N – Ethyl Thionocarbamate ≥ 95%

CAS Number

141 – 98 – 0

Other trading names

- O – Isopropyl – N – Ethyl Thionocarbamate

- IPETC

Types of Packaging

- Intermediate Bulk Container (IBC) drum with 1000kg capacity/drum

- Use plastic drums with 200 kg weight capacity per drum

HS Code:

293020

Isopropyl Ethyl Thionocarbamate (IPETC) ≥95% – Selective Copper Collector for Sulfide Ore Flotation

We supply high-purity Isopropyl Ethyl Thionocarbamate (IPETC) with a minimum 95% assay. This powerful and selective thionocarbamate collector is engineered for the efficient flotation of sulfide minerals. Consequently, mining operations actively utilize it as a primary or secondary collector for copper sulfide ores, particularly against pyrite. Moreover, its strong selectivity and collecting power make it a preferred choice for improving copper concentrate grade and recovery in complex ores.

Core Applications for Isopropyl Ethyl Thionocarbamate IPETC in Mineral Processing

This specialized collector targets enhanced performance and selectivity in copper and precious metal recovery circuits. Its application is focused on maximizing value from challenging ore types.

First, the copper mining industry relies on Isopropyl Ethyl Thionocarbamate IPETC ≥95% for the selective flotation of chalcopyrite and other copper sulfides. It demonstrates excellent performance in depressing pyrite, thereby improving the grade of the final copper concentrate. Therefore, concentrator plants processing porphyry copper and other sulfide ores depend on it for superior metallurgical outcomes.

Second, it is highly effective in the flotation of precious metals like gold and silver when associated with copper or other base metal sulfides. Furthermore, it can be used in combination with xanthates to optimize collector performance and cost-efficiency in specific ore types.

Critical Specifications for O-Isopropyl-N-Ethyl Thionocarbamate

We synthesize our IPETC to ensure high purity and consistent chemical activity. Thus, you can dose it precisely for reliable and predictable collector performance in your flotation cells.

-

Product: Isopropyl Ethyl Thionocarbamate (IPETC)

-

Chemical Family: Thionocarbamate

-

Purity: ≥ 95%

-

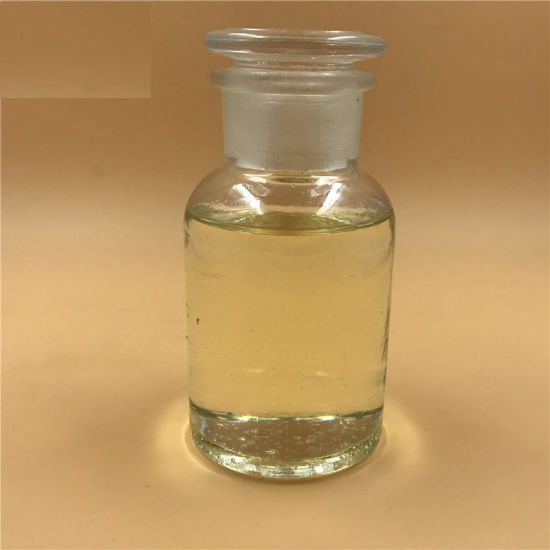

Appearance: Clear to pale yellow liquid

-

Odor: Characteristic sulfurous odor.

-

Storage: Store in a cool, dry, well-ventilated area in tightly sealed, corrosion-resistant containers. Keep away from heat, sparks, and strong oxidizers.

Your Strategic Isopropyl Ethyl Thionocarbamate Mining Reagent Partner

As your dedicated partner for advanced flotation chemicals, we provide high-performance reagents and technical support to optimize your mineral recovery.

Firstly, we guarantee high assay purity and consistent selectivity performance through controlled production and quality verification.

Moreover, we offer secure, industrial-scale packaging. We supply in 200 kg steel drums and 1000 kg IBC totes, suitable for safe handling and storage at mine sites.

We also provide competitive global pricing for IPETC ≥95%, delivering excellent value to copper mines, precious metal operations, mineral processing research institutions, and international mining chemical distributors.

Additionally, we manage reliable logistics to global mining regions. Every shipment includes complete Safety Data Sheets (SDS), Certificates of Analysis (COA), and transport documentation.

Finally, we deliver expert technical service and can support flotation optimization trials to determine the optimal dosage and application strategy for IPETC in your specific ore processing circuit.